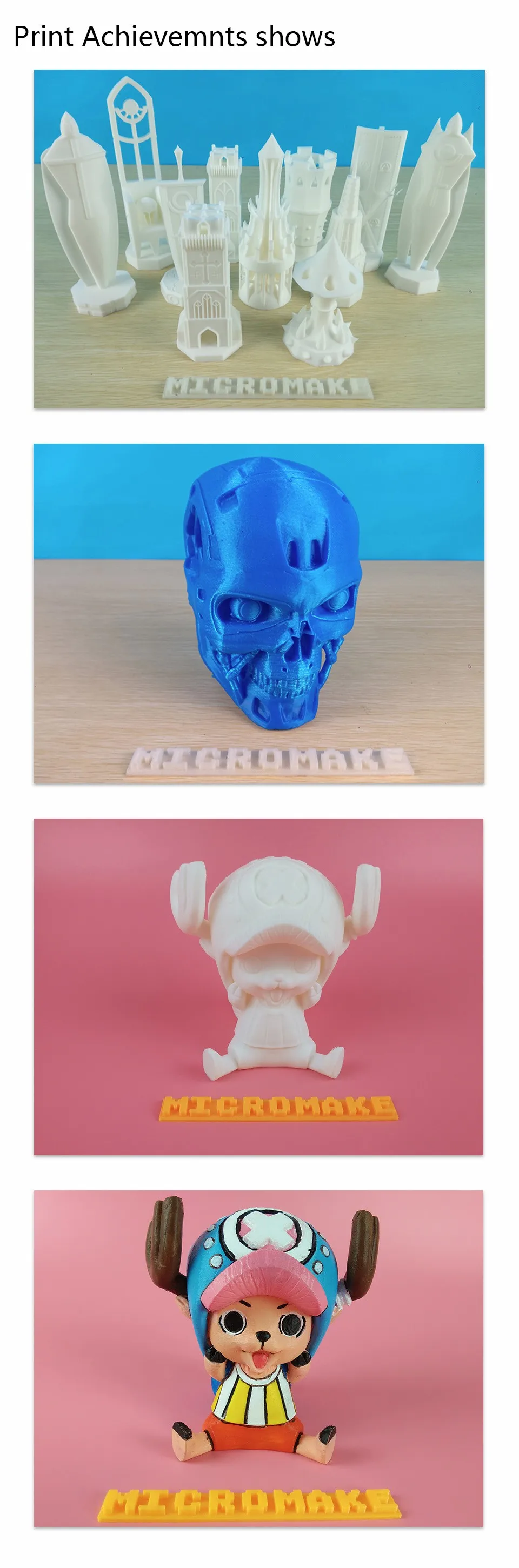

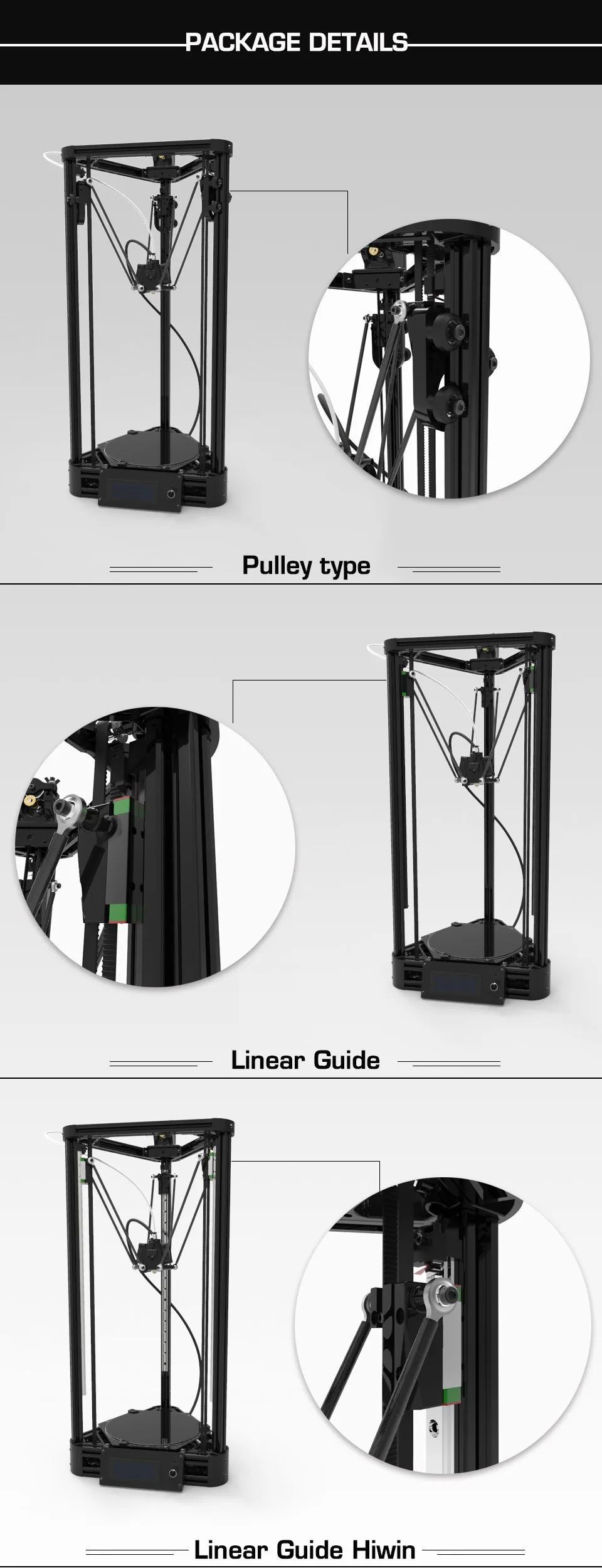

Micromake Pulley Version 3D Printer

DIY Worry-free Version 2017

Worry Free Version: On the basis of linear guide, all the connection has assembled you can finish the production with only some simple steps, and you can get extra 1kg PLA environmental materials for free. but this version doesn't include heatbed.

- Free Shipping (Lower 48 States) free shipping doesn't include the import tax

- Est 10-18 business days to deliver

- Ship from China

- Buyer takes responsibility of paying US customs duties and taxes(about 3%) if any. If you want, we will declare low value for free or low import tax

- Please provide your valid phone number which is necessary for international shipping

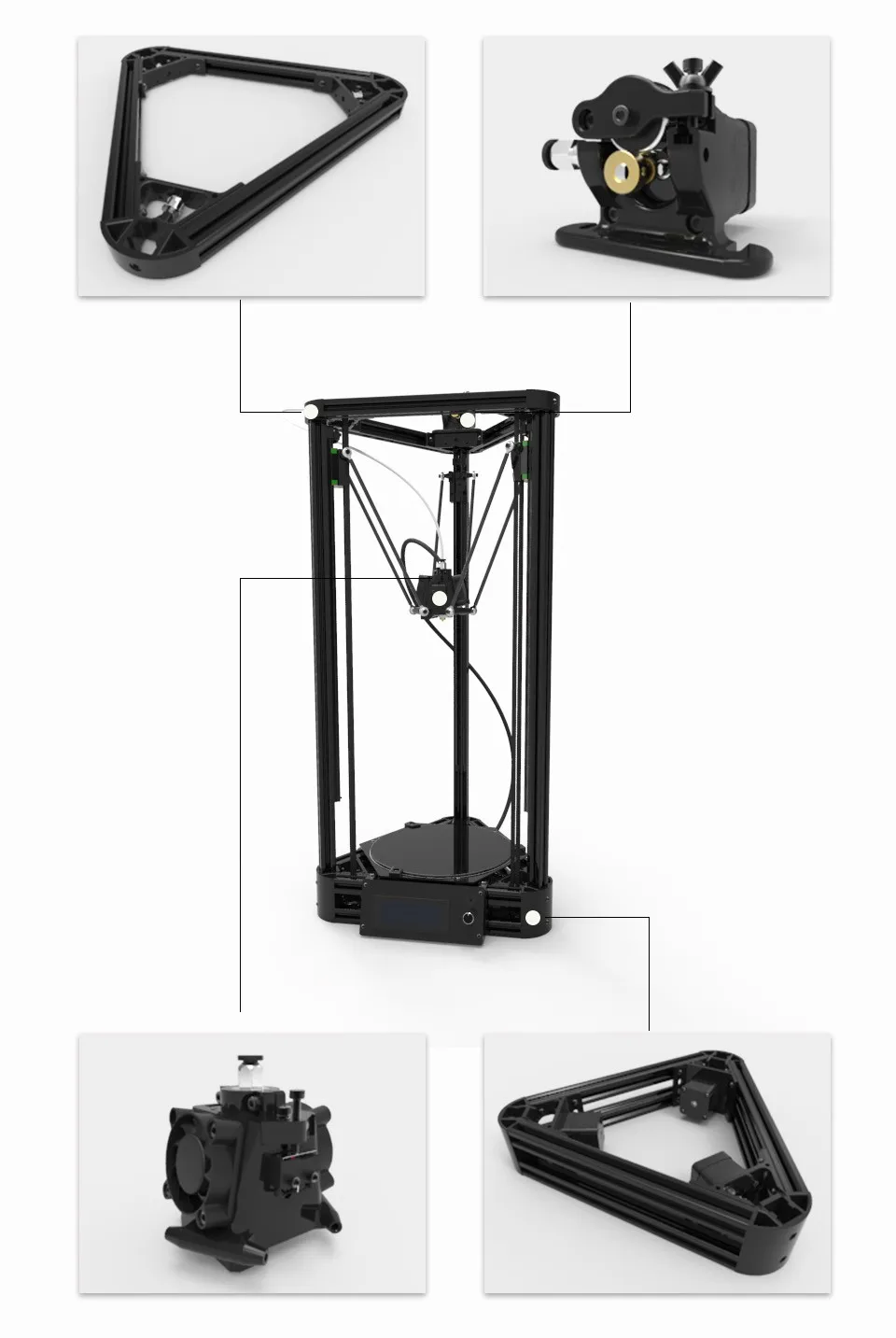

- 1.All injection molding non-standard parts

- 2.Black oxidation aluminum profile

- 3.High performance control board

- 4.Double air duct effector

- 5.High intensity extruder

- Layer resolution of 50 microns.

- MAX Printing Speed: 150 mm/s.

- Build size: Maximum 180mm*300mm,but with 180mm you need adjust many times, usually the max diameter is 160~180mm, and the max height is 300~320mm.180mm*300mm is the limit.

- Full Metal E3D V5 long distance J-head nozzle Extruder.

- Material type: PLA, ABS, wood, nylon

- Material specifications 1.75mm in diameter.

- Positioning accuracy: XYZ:0.01MM

- Printing Color: Single color.

- Nozzle diameter: 0.4mm (customized 0.3mm/0.2mm).

- Recommended extruder temperature: 240°C

- Best ambient temperature: ≥25°C.

- Power requirements:110V~220V,60W

- Connection: SD card or USB.

- The file print format: STL,G-Code.

- Compatibility: Windows,Mac

- Device Package weight: Pulley Type about 7.5 kg ,Linear Guide about 8.5

It tooks us three months to design and open mode, finally the new auto-level effector comes out. We add dedicated cooling fan to fit our well-designed double duct so that the consumble can cool quickly after it is extruded. Meanwhile, it can avoid to drop down so the effect of hollow out, high-deviated print and long-distance bridge is better. And it will need no long time to wait the previous part to cool down at the condition of high speed. With the same effect, you can use faster speed to print. We upgrade auto-level system, add spring to assist the springback, with the high precision injection molding, the accuracy of the probe improved significantly.

We redesign wire feeder completely. Aimed at the aging and deformation of the fixture of wire feeder, we use screws to fix bearing in both sides to reach the same intensity as the metal extruder and never distortion. And in order to adjust the fixture, we upgrade to butterfly nut freely.